MANAGE YOUR PRODUCTIVITY LIKE A BOSS, WITH REAL-TIME INFORMATION

MilkBOSS provides the highest level of automation to manage milking, pulsation, herd health and washing more consistently and effectively.

MilkBOSS is a whole-system solution that has been designed to be configured in a variety of ways to perform the milking and automatic detaching of cow, sheep and goat dairy milking equipment, and the precision tuning of milking pulsation.

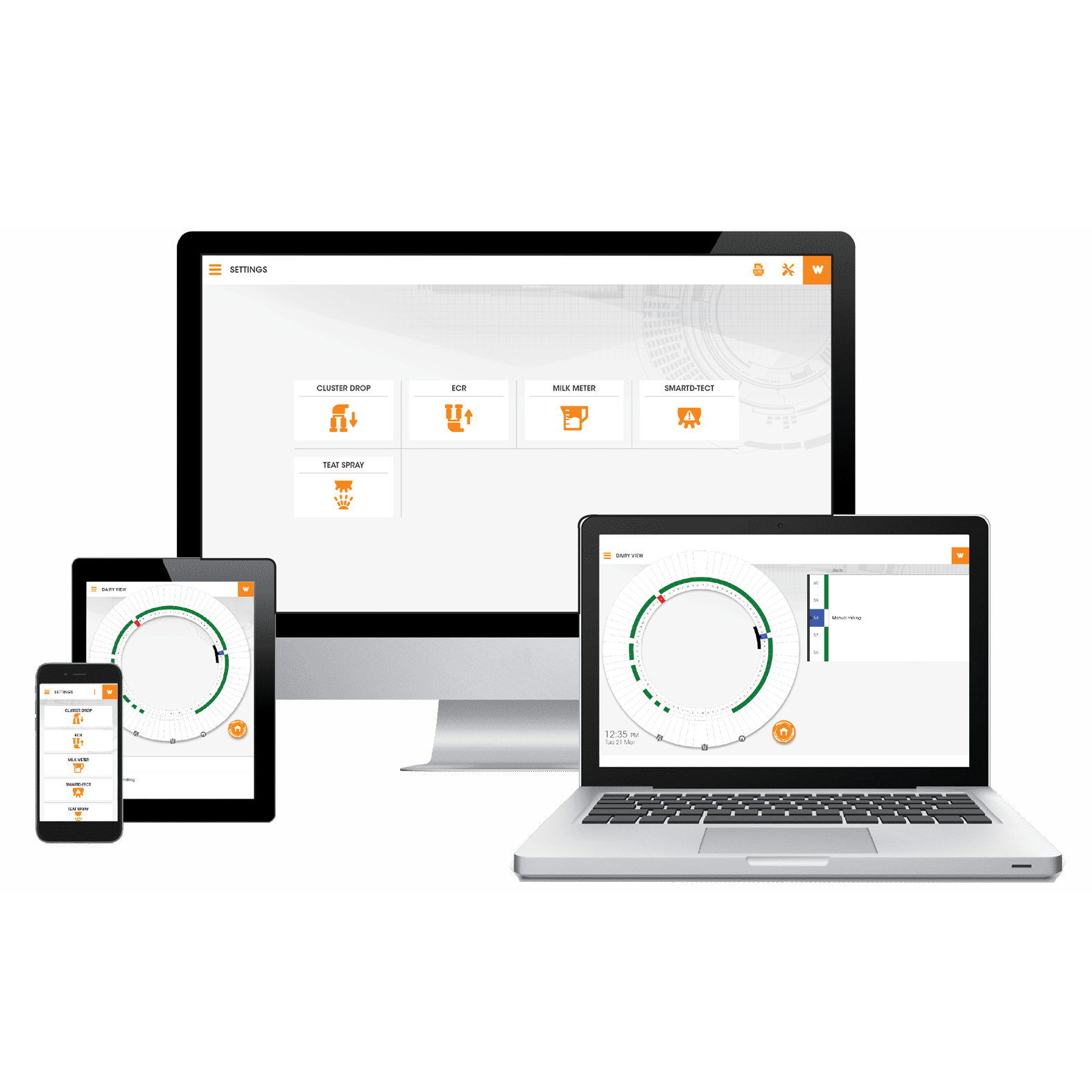

MilkBOSS also collects and monitors your important milking data including milk temperature, conductivity and milk flow/yield and delivers it via a user-friendly and intuitive visual display. The MilkBOSS system is an affordable smart automation system that can easily be retro-fitted into your existing parlor and components to provide an affordable upgrade option, or installed as a complete new parlor system.

By providing you and your operators with detailed data, MilkBOSS helps you achieve optimum milking productivity and animal health for your farm.

Advantages

MilkBOSS helps you achieve optimum milking productivity and animal health for your farm, with real-time information.

Real-time data

Real-time data allows you to attend to cows early that are displaying yield changes, high temperatures and high scc indications to prevent costly health problems occurring.

Smart Sensing Technology

Smart sensing with instant milk flow recording that provides consistency from cow-to-cow, unit-to-unit, milking-to-milking and day-to-day

No additional set up costs

No additional set-up or customization costs – operator can set exact pulsation ratios, end-of-milking flow rates and many other production and procedure related settings without a dealer technician.

Patented CT-Logic

Patented CT-Logic™ to identify sick cows more consistently than other systems.

What's included

- TrackerAir software: The MilkBOSS software to view milking performance in your parlour, and control settings and milk flow parameters.

- Mounting brackets: Bracketry to suit a range of different parlour installations, including Tie stall, Rotary, Parallel, and Swingover systems.

Package options

BASE STALL CONTROL

The MilkBOSS unit is the core of the stall control group - enabling the running of pulsation, retract actions and milking management. Start here to build from the ground up.

SWING ARM PACKAGE

Enabling the conversion from a free-standing parlor to automation without outfitting both sides with individual stall equipment - the proven Swing Arm configuration is quality automation for existing parlors.

TIE-STALL PACKAGE

The performance proven all-in-one unit, the Tie Stall version of MilkBOSS has evolved from the most durable and reliable milking unit in free stall parlors for over 20 years.

PARLOUR PACKAGE

Bringing the detach function “onboard” into a compact, easily installed unit -the MilkBOSS parlour package is easily the best option for both upgrade and new parlour installations.