Reduce labour. Increase productivity

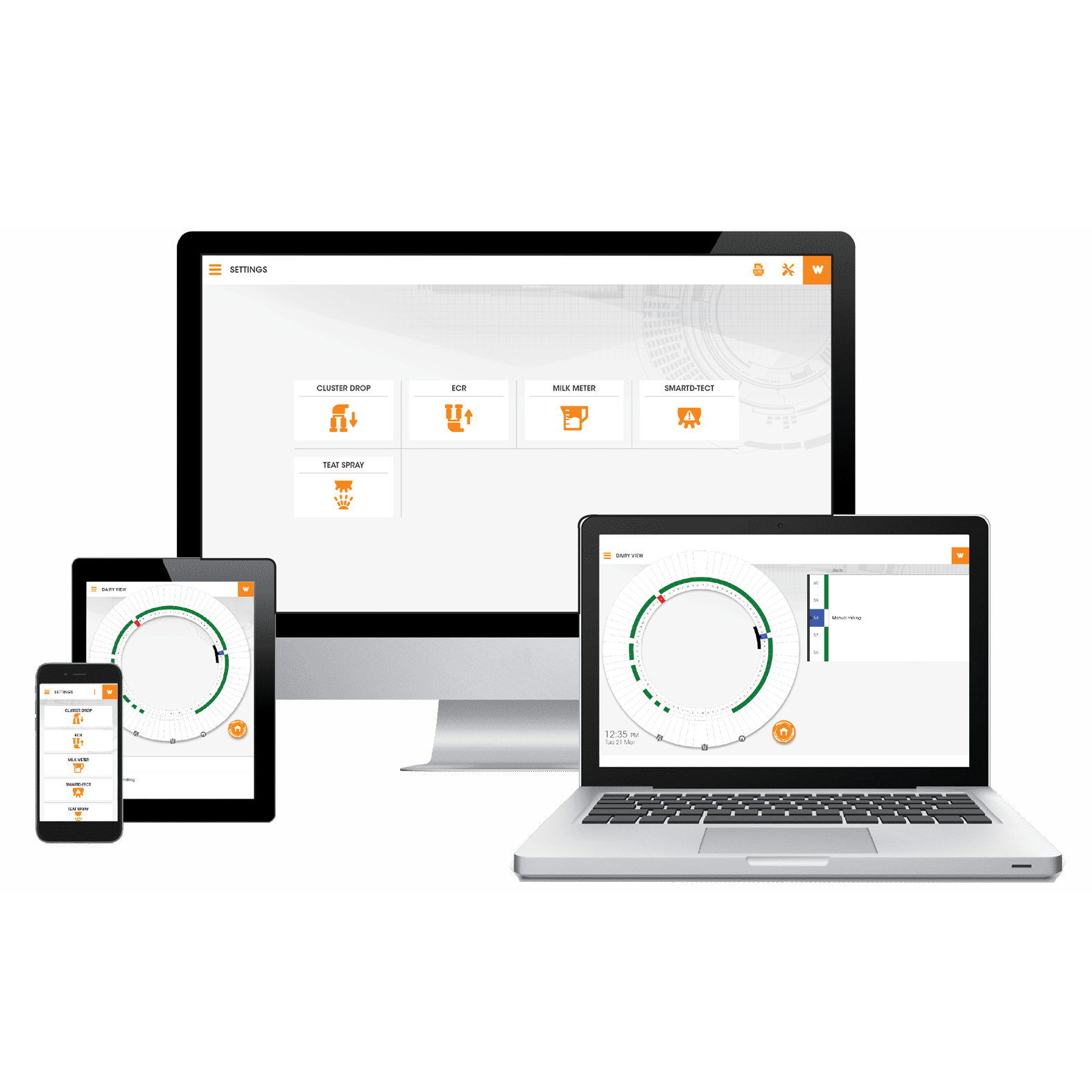

SmartD-TECT performs a health analysis of each quarter of the udder by automating your pre-milking stimulation and udder health monitoring without adding additional tasks for the operator.

SmartD-TECT allows you to make data-driven decisions for your herd’s health reducing the chance of any loss in productivity. The pulsator milks each quarter separately to measure the conductivity of each teat during the pre-milking phase. Individual quarter conductivity allows SmartD-TECT to eliminate issues with dilution between quarters to provide highly accurate alerts for potential health problems. If any quarters are abnormal, an alert is issued up to four days before visual signs appear, providing the opportunity for early treatment intervention. The pre-milking pulsation for quarter testing also promotes a natural let down response from the cows, eliminating precious time normally spent manually stimulating teats to trigger milk flow. By having the same milking routine each time, cows let their milk down faster, more consistently and at a higher average flow rate. By removing the variabilities of operators, SmartD-TECT provides consistency in performance and productivity advantages that no other conventional milking system offers.

Advantages

SmartD-TECT provides the peace of mind of a consistent milking routine and the automated detection of problem animals and potential udder health issues, reducing the treatment time and cost.

Udder Health Monitoring

Identify the onset of mastitis up to four days before visual signs are evident to make decisions earlier.

Individual Quarter Testing

The pulsator milks each quarter separately and measures the conductivity of each for a more accurate alert.

Eliminate Forestripping

Automate your milking stimulation and prep routine to reduce labour and increase your productivity.

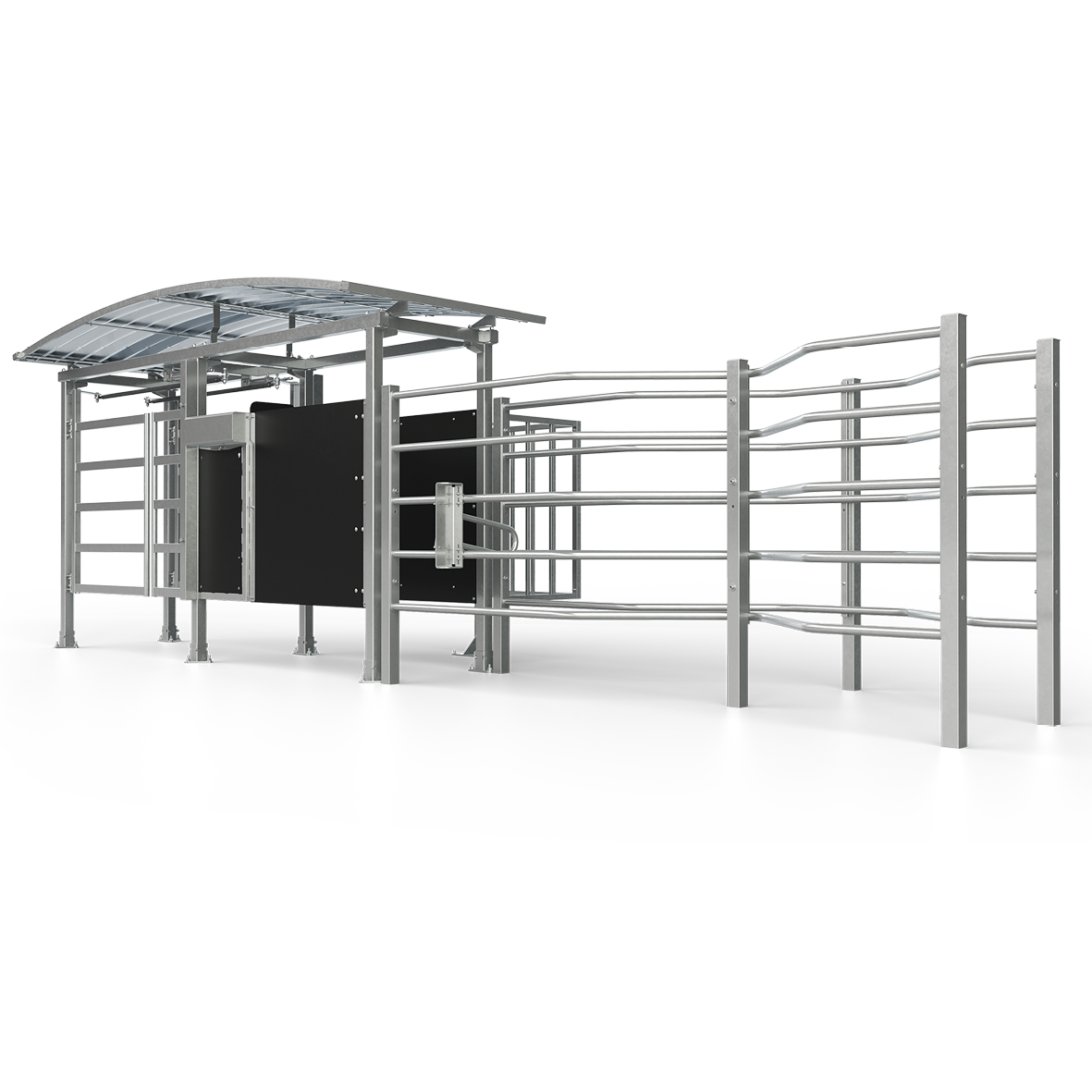

What's Included

- SmartD-TECT Pulsator: Controls individual pulsation signals to the cluster allowing each quarter to be milked separately at the start of milking.

- SmartD-TECT Sensors: Are attached to the milk line at every cluster to measure the conductivity of the milk from each cow. The results are sent to the pulsator for interpretation.

- SmartD-TECT Controller: Is a touchscreen interface that controls SmartD-TECT’s sensitivity settings.