Accurate and reliable, saving labour costs

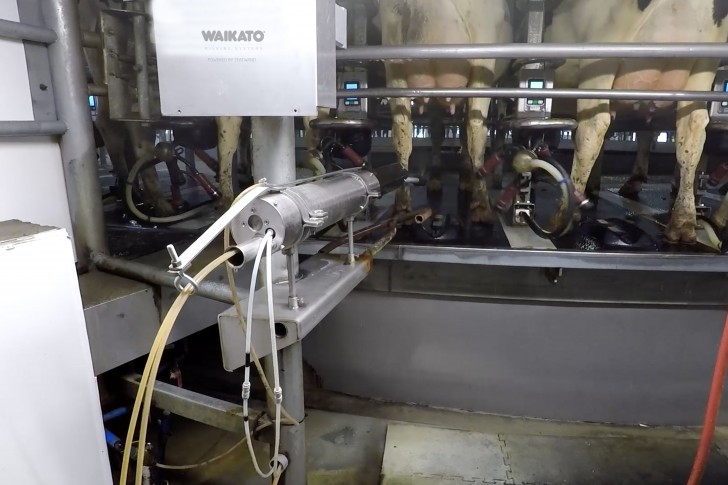

The Waikato Spray Arm is a game changing automatic system for large fast-moving rotaries.

The Waikato Spray Arm system allows for pre-spray and/or post-spray units to be installed, removing expensive labor units from your operation. A series of advanced sensors accurately locate the cows position on the platform as she nears the exit / entry areas. This information is then communicated directly to the controller. The stall sensors determine the direction of the platform, measures the speed and activiates a spray sequence. The cow sensor detects if there is a cow in the stall. No cow, no spray, no waste. Thorough teat spray coverage of all four teats is achieved with the use of two independently controlled spray nozzles in each arm, that extend under the cows’ udder as the rotary platform passes. The Spray Arm Controller can easily adjust the sequencing and spray volumes to suit your requirements. MODELS AVAILABLE: Waikato Spray Arm Exact: Single spray arm mounted on a stationary pole. Sprays each stall as it passes. Suitable for 78 point and below. For speeds as fast as 5.5sec/stall. Waikato Spray Arm Rapid Dual: Two spray arms mounted on a stationary pole. Sprays each stall as it passes. Suitable for 80 points and above. For speeds as fast as 3.8sec/stall.

Advantages

Easy to install

Easy to install and inexpensive to maintain

Reliable and precise spray pattern

Advanced sensors accurately locate the cow.

Affordable Automation

For large, fast moving rotaries.