Milking time has been cut in half thanks to key milking automation technology.

With a 300 year family farming legacy behind them, the Morris-Eyton’s embarked on a journey in 2019 to take their dairy operation and milking performance to the next level. The family farm is owned by Robert and Rowena Morris-Eyton, with their son Patrick and his grandmother as business partners as well.

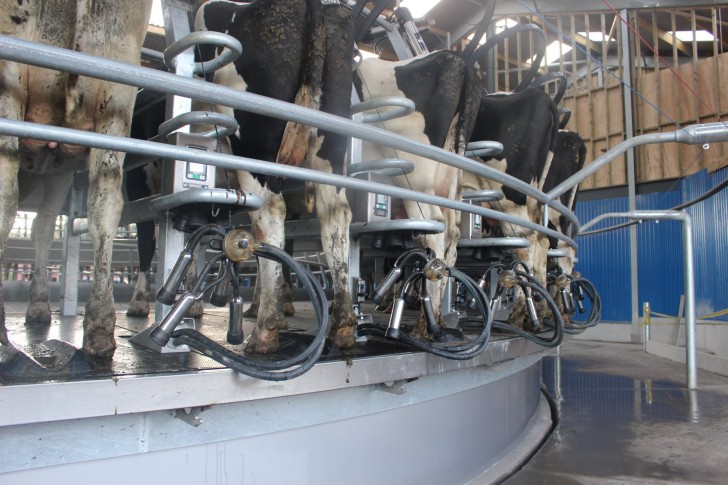

While the farm’s old 12/24 herringbone system had been updated over time, it was starting to show its age - taking them three hours each morning and afternoon to milk their 210 cows. Wanting to increase their herd size and milking efficiency, they chose the premier and award-winning Centrus Composite Rotary Platform.

“We wanted to expand and one of our requirements was to be able to milk 200 cows per hour for one person as a minimum” says Patrick.

The new Centrus Composite Rotary was installed and commissioned in October 2019. Patrick says it has delivered the efficiencies they were looking for “having cut milking times in half easily” without having to push people to work faster than a comfortable speed.

To reduce their milking time Beckside Farm’s fitted milking automation to their Centrus Composite Rotary parlour. The technology included Electronic Milk Meters to record milk data - which is a requirement of their contract. SmartECR automatic cup removers were installed to ensure the clusters are removed at the correct time, which also assists with udder and teat health. And because they previously had an automated teat spray system, they installed SmartSPRAY to greatly increases efficiencies, while reducing labour during milking. “It means there is one less job to do when milking if it can be done automatically” says Patrick.

The new parlour was also fitted with the Waikato Milking Systems, NaviGate Dairy Management System to gather milking automation data on each cow so the farmer can make better management decisions for the herd.

As part of their research into the redevelopment they spent time talking to farmers with rotaries, and decided to go with Waikato Milking Systems because of the composite deck on the Centrus platform. “It is much lighter than a traditional concrete deck therefore, less wear on the running gear” says Patrick.

Patrick’s research also showed the Centrus Composite Rotary deck had a higher level of resistance to chemicals, compared to concrete platforms.

Feedback from other farmers on Beckside Farm’s redevelopment has been positive “They liked the milking automation technology, which allowed the milking parlour to do more but with fewer hours spent in the parlour. They also saw that working with the Centrus Composite Rotary was easier on the animals and the operator.” says Patrick.

Patrick’s advice to farmers looking to redevelop their old dairy parlours is “don’t cut corners on technology that can make your life easier.”

Specifications

- Centrus Composite Rotary Milking System

- 54 Stall

- 210 Cows

- Commissioned: 2019

- Pivot Rollers

- SmartD-TECT

- Electronic Milk Meters

- SmartECR

- SmartDRIVE Milk Pump Controller

- SmartWASH

- SmartDRIVE Vacuum Pump Controller

- SmartSRPAY

- NaviGATE Premium