INTELLIGENT AND INTUITIVE PARLOUR MANAGEMENT

Automate your parlour management to drive your milking productivity and performance, and elevate the value of your dairy operation through precision dairy farming

By incorporating the DairyHQ™ Parlour Management System alongside your Waikato Milking Systems automation equipment, you can make better decisions to optimise your milking operation and profitability.

There are several critical factors that impact dairy farming profitability including efficient labour utilisation, enhanced working conditions, optimal resource management, and data-driven decision-making. DairyHQ™ allows you to harness these resources to your advantage, by continually monitoring and overseeing key aspects of your milking operation.

This enables you to focus on accurately recorded and processed data to make informed decisions - including animal breeding for genetic enhancement, herd culling, precise feed budgeting, and optimally timed artificial insemination.

In doing so, you can significantly reduce wastage across various aspects of your parlour, from feed costs to veterinary expenses, to energy consumption. This data-driven decision making enables you to fine-tune your herd, resulting in a stronger, more productive, and more efficient operation.

LEARN MORE ABOUT

Dairy HQ's Animal ID, Feed customisation, milking data and automatic sorting.

DAIRYHQ™ ID

DairyHQ™ ID is an advanced animal identification system that reads an animal’s RFID tag and assigns unique animal management numbers to milking points, streamlining in-bail feeding, and data collection during milking.

By accurately identifying and collecting precise data for each animal in the milking point, DairyHQ™ ID eliminates the need for the constant monitoring of each animal during milking and manual record-keeping. The system makes data collection and management more efficient to enhance decision-making, increase efficiency and increase profitability. DairyHQ™ ID provides seamless integration into Waikato Milking Systems milking point controls, and features a modern user interface on a range of digital devices, and is designed in conjunction with farmers, for farmers.

DairyHQ™ FEED

DairyHQ™ FEED provides feed allocation to individual animals based on animal-specific parameters to ensure efficient feed utilisation to improve health, growth and milk production.

By identifying each animal from DairyHQ™ ID data, the system extracts each animal’s allocated feed ration and dispenses the correct feed recipe to the animal. This prevents the wasteful inefficiency of blanket feeding that overlooks individual animals’ needs. DairyHQ™ FEED’s customised feed rations based on specific groupings maximises feed budgets. It also allows adjustments, especially during adverse weather conditions, leading to enhanced production and improved animal health. With native multi-feed type dispensing, intuitive feed head calibration, and comprehensive feed reporting, DairyHQ™ FEED allows for the seamless management of up to six types of feed. The 24V DC outputs interface with feed head control contactors ensuring precise operation. Standalone blanket feeding is available in the event of the system going offline.

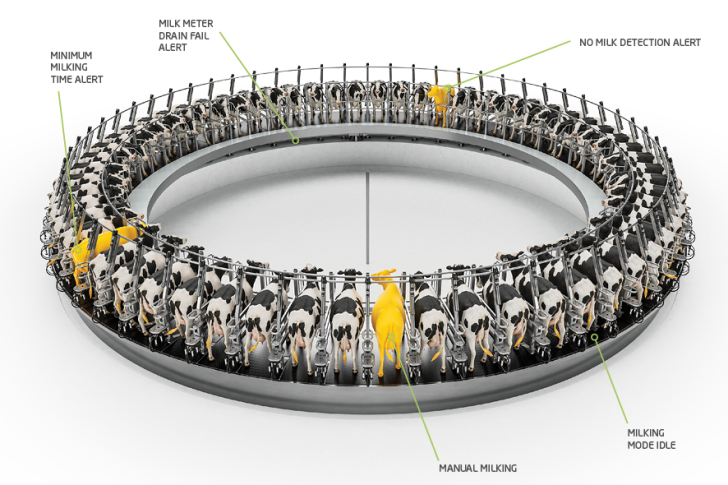

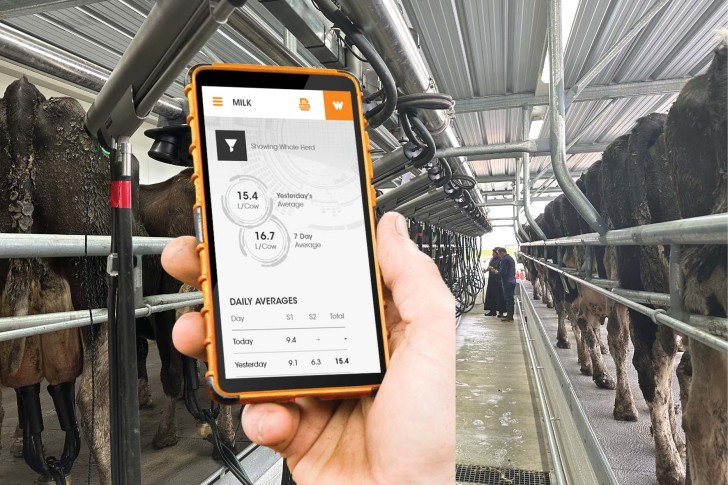

DairyHQ™ MILK

DairyHQ™ MILK collects detailed animal milking data from your milking machine and associates it with specific animals in your herd*, so you can monitor their milk performance and output. It then presents this information in a user-friendly format, making it easy for you to access and understand.

The system connects seamlessly with your Waikato Milking Systems automation equipment and communicates directly with the DairyHQ™ server via the DairyHQ™ MILK controller. As your cows are milked, various status messages are relayed to the DairyHQ™ server, such as milking start and end times, alerts, yield information, and more. DairyHQ™ captures and logs this data for each animal, creating a comprehensive picture of the milking process.

DairyHQ™ SORT

A key challenge farmers face is ensuring reliable animal sorting to avoid issues with poor mating spread and animal health caused by missing animals in the sort.

DairyHQ™ SORT effectively resolves these issues by providing reliable automatic sorting - which significantly reduces the labour required in the parlour. The system provides several benefits, including the ability to easily add animals to the sort list during milking, either through the user console or a mobile device. Head and/or health alert animals are also automatically added to the sort list via the CowTRAQ™ interface.

DairyHQ™ SORT also allows for the easy importing of CSV sorting lists for larger sorts, making it a versatile solution for your farm.