PEACE OF MIND THAT COWS ARE SPRAYED EVERY TIME

A smarter way to spray more accurately and reliably

With teat health being paramount in ensuring the best possible milk quality and health care for their cows, the SmartSPRAY automatic teat spray system was at the top of Totman Dairies’ list of key technologies when they decided to upgrade and refit their old milking plant in the Waikato.

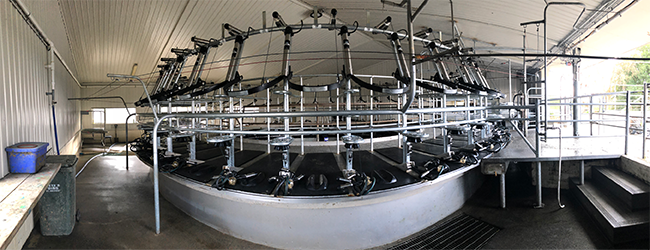

Prior to upgrading to their new Waikato Milking Systems 40-point rotary milking system in 2019, Totman Dairies had been using an older style automated teat spray system at the plant’s exit point - where the cows were sprayed as they walked out of the shed. After undertaking research on teat spray application, Business Manager Aaron Olesen and his team decided on an in-bail system where the spray could be applied directly a few seconds after the cups were removed. “That’s the optimum time to spray, when the teat canal is still open,” says Aaron.

The Waikato Milking Systems SmartSPRAY system is designed specifically for this type of application in rotary dairies, and replaces the need for manual teat spraying and teat dipping before and after milking. Other than refilling the spray tank every three days, which is easily accessible on the outside of Aaron’s rotary platform, “There is little operator input required to maintain the SmartSPRAY system,” he says.

There was also no effort required to transition the 700-cow herd to the new SmartSPRAY system, “I don’t even think the cows noticed the difference when they went on to the rotary for the first time because the spray is released in a very fine mist.” Since installing SmartSPRAY Aaron says the system has performed “without fault, and is very reliable,” and he has noticed an overall improvement in his herd’s teat health condition, “because the spray is applied accurately and correctly at morning and afternoon milking times, without fault.” The adjustability of the SmartSPRAY system to ensure the best possible application of the spray was also a big bonus for the farm. This means the operator can “get the timing right,” says Aaron in terms of setting the spray to activate a few seconds after the cups are removed, clear of the cow.

For Aaron the main advantage of the SmartSPRAY system has been its reliability and proven performance in teat health condition. “It’s just given me peace of mind that the cows are going to be properly sprayed every day and every night. It’s a job that gets done without even having to think about it.”

Totman Dairies also added other automation features to their new rotary milking system during the refit by their dealers Qubik Putaruru and Moa Rotary Platforms - which have all performed up to Aaron’s expectations. This included installing ECR Plus electronic cup removers which were also fully adjustable and able to be removed from the cows at a time specified by the operator. ECR Plus also controls the SmartSPRAY system and the automatic cow restraints.

The Milk Recovery System on the rotary uses compressed air to force residual milk into the vat, which is saving about 80 litres per milking time. The Vacuum Pump on the rotary also ensured there was next to no vacuum loss during milking which was critical for the cup removers to perform properly. Aaron also switched over to lightweight shells for milking which had dramatically reduced cup slippage.

“This is just a small rotary, only 40 bails, but it is certainly efficient and reliable thanks to the automation technology we added in 2019.”

Specifications:

- Customer: Totman Dairies

- Platform Refit

- 40 Bails

- 700 Cows

- Completed: 2019

- SmartSPRAY

- BailGATE Straps - Cow Restraints

- BailMATE

- ECR Plus - Automatic Cup Removers

- Rubber Mats (fitted to original deck)

- Waikato 320 Claw

- SmartDRIVE

- SmartPULS