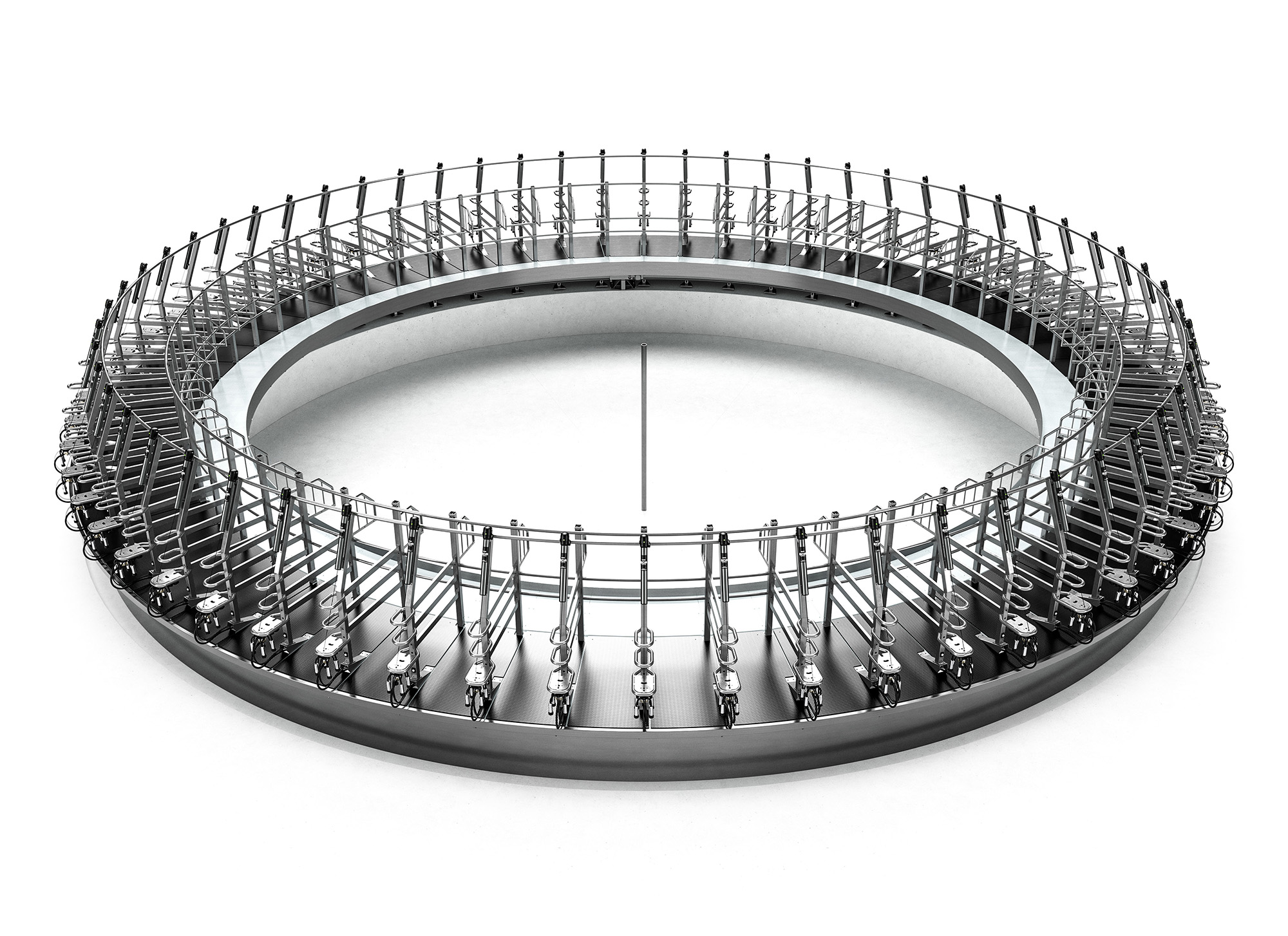

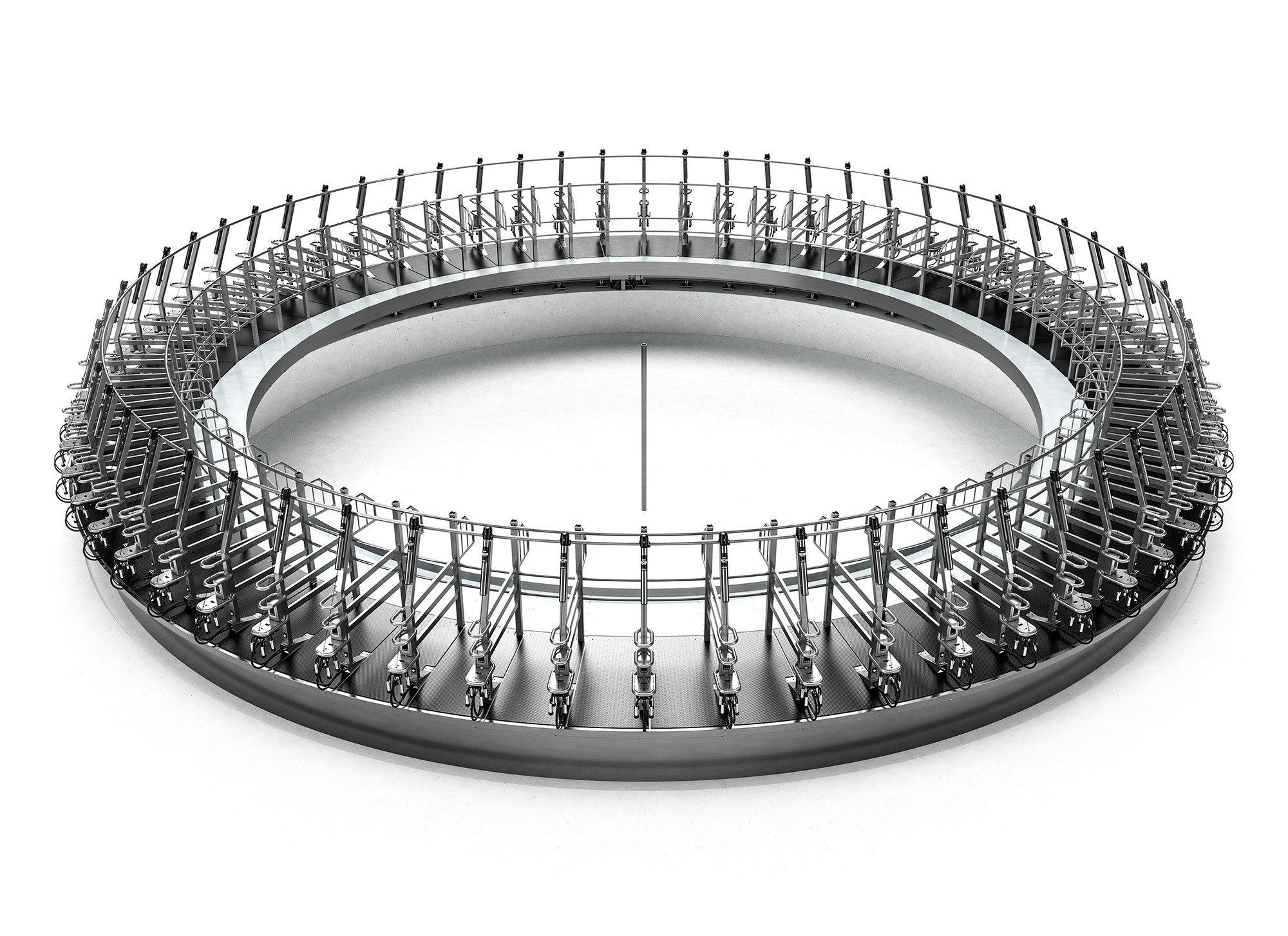

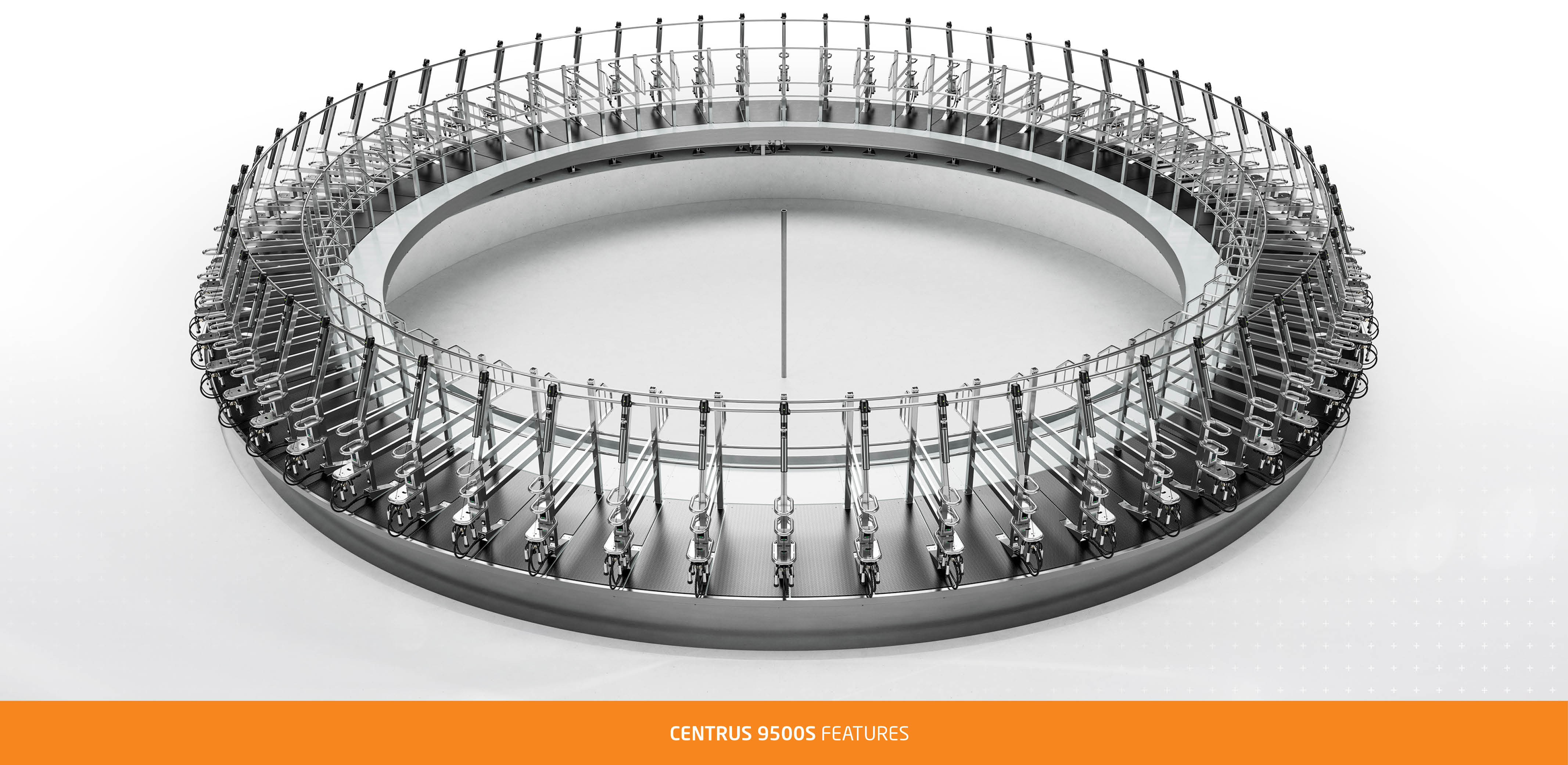

INDUSTRIAL ROLLERS, STAINLESS STALLING, INDUSTRIAL-LEVEL EFFICIENCY

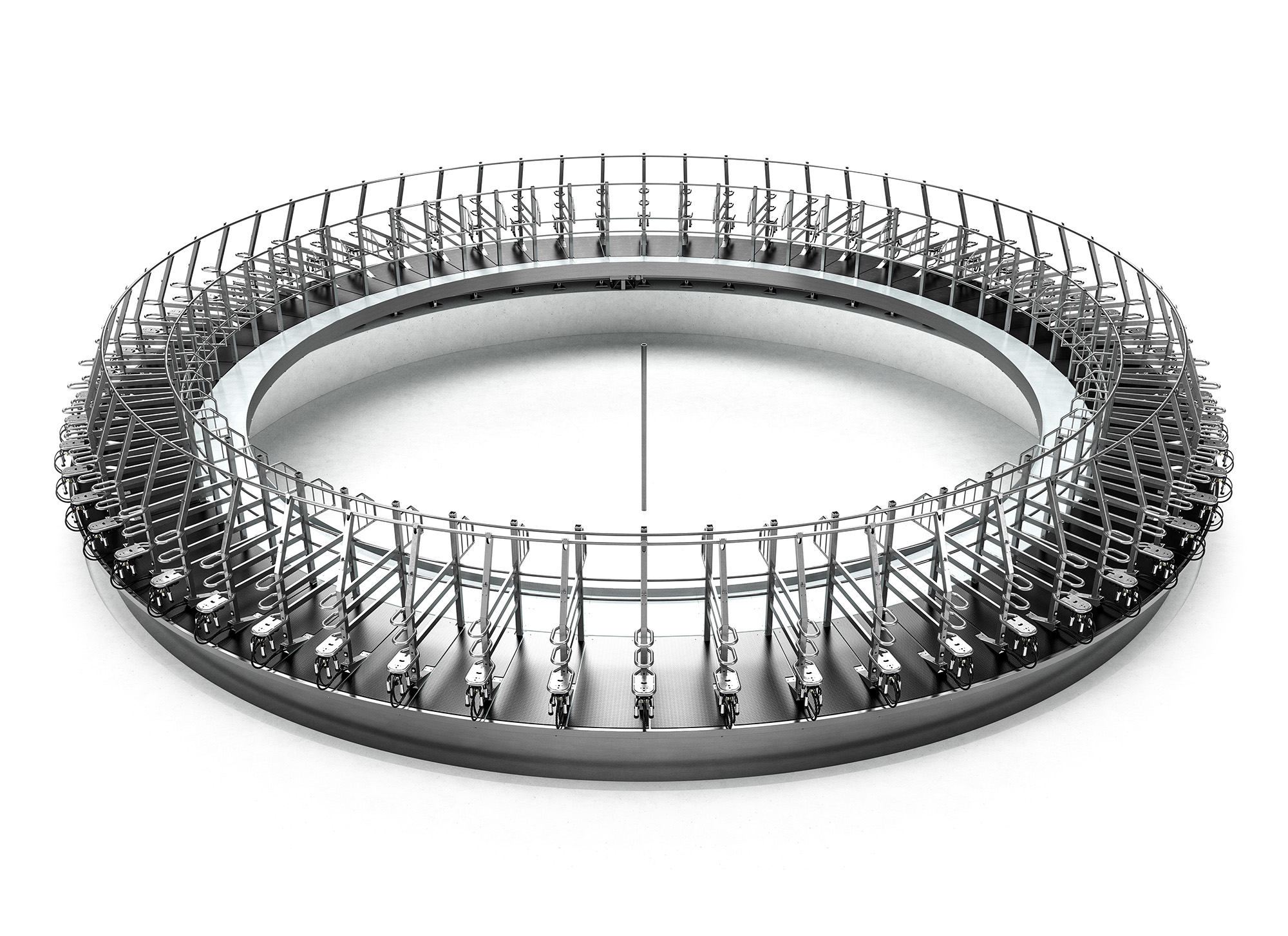

The Centrus 9500s provides a fully automated, ground-breaking system that is designed to never stop turning, so you can run a more productive, cost-efficient and profitable operation.

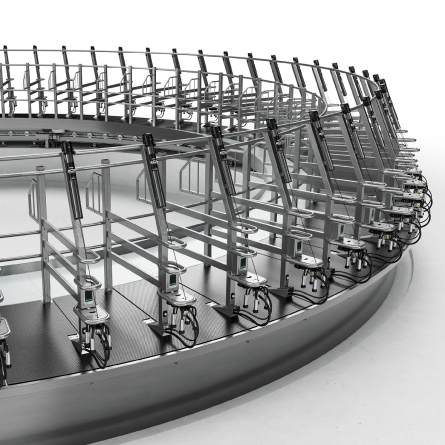

Constructed from high-performance composite materials, the Centrus 9500s features industrial rollers which reduce the point loading on 24/7 operations. The stainless steel heavy duty stallwork is resistant to chemical spray and effluent and is easier to clean and maintain. The Centrus 9500s is designed to be structurally stronger, lighter and longer-lasting. The system has been designed to ensure a comfortable and enjoyable milking environment for the operator and is ergonomically correct for cows, providing a quiet and stress-free milking for all.

Advantages

See how the Centrus 9500i saves on time and labour and provides maximum industrial-level efficiency.

Unmatched performance and longevity

The multi-layered laminated composite deck is up to 75% lighter, structurally superior, and more durable than traditional concrete or steel alternatives

Automated for maximum efficiency

A full automation suite gives real-time data along with animal health and performance monitoring.

Strong, durable stainless steel stallwork

Resistant to chemical spray and effluent, stainless steel stallwork is low maintenance, easy-to-clean and maintain.

What's included

• Rated Operating Duty per Day = 24 hrs

• Extra Comfort Bail Width (980mm c/c outer rim)

• Heavy duty Stainless Steel Stallwork

• Double Beam with nylon rollers to suit 24/7 systems, at approx. 450mm spacing

• Lightweight, Heavy Duty Composite Deck

• Drive Units & Cups On Controls

• Heavy duty galvanised sub frame

• Extra wide 2.7m platform

• Rubber mats for cow comfort

• Automatic lubrication system

• Full circumference control and emergency stop ropes

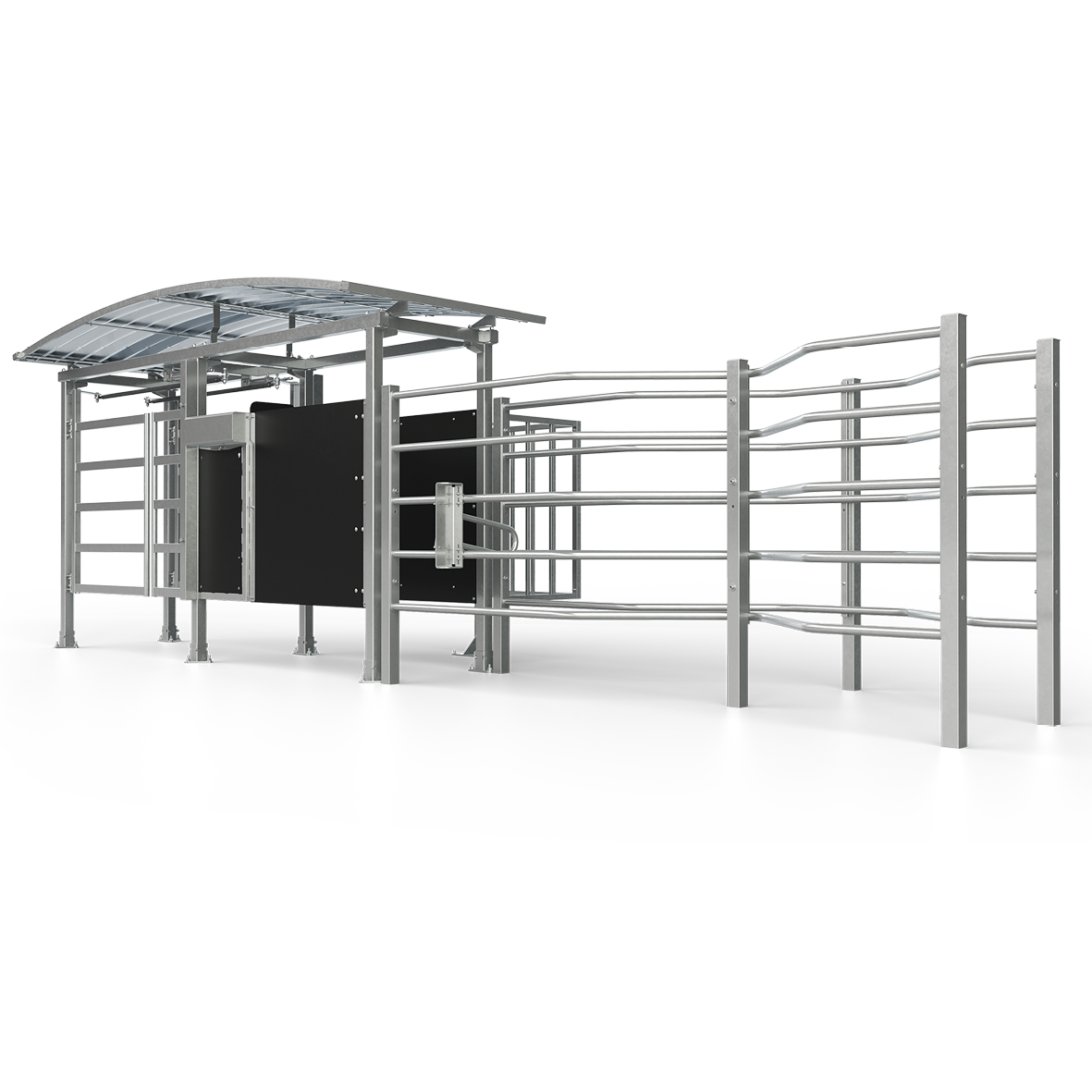

• Entry crush switch

• Entry D-Gate Assembly

• Full circumference rump and kick rail

• Stainless steel dry edge